United Filters International manufactures numerous specialty filters for a wide variety of industries and applications including potable water treatment, viscous fluid filtration, high contaminant load, and high purity applications.

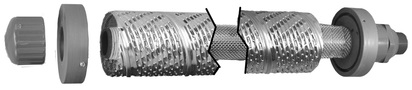

UFI Stainless Steel "Scavenger" Filters are specified for high contaminant load.

Features of the Scavenger Filter:

Features of the Scavenger Filter:

- Available in 18 to 72-inch lengths

- Double open ended/Buna available

- 150 psi differential operating pressure

- Available in 20 to 250-micron nominal micron ratings

- Housing interface of .5-inch, .75-inch and 1.0-inch NPT/DOE

- No tools required for field cleaning and parts replacement

- All stainless steel/PVC construction for fluid compatibility

- Cleanable without tools

CUTAWAY OF THE SCAVENGER FILTER

United Filters International has continually served the filtration needs of the Gas and Petrochemical lndustry for over 30 years. UFl's warehouse is ideally located in Amarillo, Texas, with an extensive inventory ready to support those critical times when rapid turnaround is needed for those unpredictable “upsets”.

UFl's filters are manufactured from both natural and man-made media’s which include but are not limited to: cotton, nylon, fiberglass, rayon and polypropylene materials. Clay and Zeolite filled cartridges are also available. Cores and end caps are matched to interface with new or existing vessels. These caps and cores are manufactured using polymer or various metals to meet the needs of our customers.

United Filters provides Dual Wind Cartridges which are particularly suitable when the contaminants within the liquid cover a broad range of particle sizes. The more open outer winding traps the larger particles while the tighter internal wind captures the smaller, fine micron particles.

This dual wind product provides longer cartridge life without altering the efficiency of the filter element. Several field applications involving Dual Wind elements have similarly resulted in three times the normal filter life with equal or superior efficiency over single micron rated elements. Dual Wind elements are available in various media, core, end cap and micron ratings to meet your specific requirements.

UFl's filters are manufactured from both natural and man-made media’s which include but are not limited to: cotton, nylon, fiberglass, rayon and polypropylene materials. Clay and Zeolite filled cartridges are also available. Cores and end caps are matched to interface with new or existing vessels. These caps and cores are manufactured using polymer or various metals to meet the needs of our customers.

United Filters provides Dual Wind Cartridges which are particularly suitable when the contaminants within the liquid cover a broad range of particle sizes. The more open outer winding traps the larger particles while the tighter internal wind captures the smaller, fine micron particles.

This dual wind product provides longer cartridge life without altering the efficiency of the filter element. Several field applications involving Dual Wind elements have similarly resulted in three times the normal filter life with equal or superior efficiency over single micron rated elements. Dual Wind elements are available in various media, core, end cap and micron ratings to meet your specific requirements.

UFI offers a wide variety of specialty filters for all of our specialty housings and vessels. many of these filters require critical pressure, purity and media specifications.

Multi-pleat High Flow Series Filter Cartridges

High Flow Pleated Cartridges Incorporating Proprietary Melt Blown Filter Media

High Flow Pleated Cartridges Incorporating Proprietary Melt Blown Filter Media

- Very High Surface Area per Cartridge-High Flow Rates, Long Service Life and Reduced Maintenance Costs

- Inside to Outside Flow Configuration-All Contaminants Held Within the Single Open Ended Filter

- Available in 20", 40" and 60" Lengths

- Proprietary Filter Media Produced for Highly Consistent Performance

- Fixed Pore Construction – Resists Dirt Unloading at High Differential Pressures

- Polypropylene Construction-Inert to Many Process Fluids Ensuring Wide Chemical Compatibility

- Various Gasket/O-ring materials-compatible with Many Fluids

- Manufactured in a Class 1,000 Clean Room Manufactured Under a Certified ISO 9001 Quality System

| 5_multipleat,_high_flow,_pleated_bag_filters.pdf | |

| File Size: | 1365 kb |

| File Type: | |

POLY-ADCT Series Filter Cartridges

Advanced Polypropylene Melt Blown Filter Cartridges with Polypropylene Core for Demanding Applications

Advanced Polypropylene Melt Blown Filter Cartridges with Polypropylene Core for Demanding Applications

- Retention Ratings from 0.5um to 75um

- Graded Pore Structure Increases Dirt Holding Capacity and Filtration Efficiency

- Proprietary Center Core for Greater Mechanical Strength

- Easy and Safe Cartridge Incineration or Disposal -100% Polypropylene Construction

- Free of Surfactants, Binders, Anti-static Agents and Adhesives

- All Materials are FDA Listed for Food and Beverage Contact

- Double Open End and Single Open End Cartridge Configurations Available

| 4_poly-adct,_mb,_core_cartridge.pdf | |

| File Size: | 1349 kb |

| File Type: | |

Superior-Fine Series Filter Cartridges

100% Polypropylene Melt Blown Cartridges with a Fixed Pore Structure That Deliver High Dirt Holding Capacity and Consistent Performance

100% Polypropylene Melt Blown Cartridges with a Fixed Pore Structure That Deliver High Dirt Holding Capacity and Consistent Performance

- Graded Pore Structure Increases Dirt Holding Capacity and Filtration Efficiency

- Proprietary Inter-Zone Bonding Process Provides a Rigid Filtration Structure that does not Compress as the Differential Pressure Increases

- High Purity Material Allows Optimization of the Filtration Media for Longer Life and Higher Efficiencies

- Easy and Safe Cartridge Disposal via Incineration, Shredding or Compaction

- 100% Polypropylene Construction – Non-Fiber Releasing Matrix

- Cartridges are Free of Surfactants, Binders, Anti-static Agents and Adhesives

- Materials are FDA Listed for Food and Beverage Contact

- Materials are NSF Certified

| 3_super-fine_mb_filter_cartridge.pdf | |

| File Size: | 1318 kb |

| File Type: | |

Fine BB Series Filter CartridgesLarge Diameter Polypropylene Melt Blown Cartridges

- Graded Pore Structure Increases Dirt Holding Capacity and Filtration Efficiency

- Easy and Safe Cartridge Incineration or Disposal

- 100% Polypropylene Construction

- Free of Surfactants, Anti-static Agents, Binders and Adhesives

- All Material Meet FDA Requirements for Food and Beverage Contact

- Special Outside Diameter of 4.3” (110mm)

- Can Retrofit Most Existing Cartridges Used in Large Diameter Housings

| 2_puris-fine_bb_series_filter_cartridge.pdf | |

| File Size: | 2574 kb |

| File Type: | |

HIE Series Filter Cartridges

High Surface Area Pleated Cartridges to Retrofit Bag Filters.

High Surface Area Pleated Cartridges to Retrofit Bag Filters.

- High Flow and Contaminant Holding Capacity

- Proprietary Filter Media Delivers Highly Consistent Performance

- Fixed Pore Construction – Resists Contaminant Unloading at Maximum Differential Pressure

- Inside-Out Flow Traps Dirt Inside the Cartridge Eliminating Downstream Contamination During Change Out.

- Available to Fit Most Size 1 and Size 2 Bag Housings with No Hardware Changes

- Polypropylene Construction – Inert to Many Process Fluids Ensuring Wide Chemical Compatibility

- Various Gasket/O-ring Materials – Compatible with Many Fluids

- Cartridges Can Be Manufactured to Customized Lengths to Retrofit Unique Bag Lengths

- Manufactured in a Class 1,000 Clean Room

- Manufactured Under a ISO 9001 Quality System

| 6_hie,_pleated,_poly_pro_bag_filter.pdf | |

| File Size: | 1834 kb |

| File Type: | |

Fine Series Filter Cartridges

High Purity Polypropylene Melt Blown Cartridge can be Used in a Wide Range of Applications

High Purity Polypropylene Melt Blown Cartridge can be Used in a Wide Range of Applications

- Graded Pore Structure Enhances Dirt Holding Capacity and Filtration Efficiency

- Easy and Safe Cartridge Incineration or Disposal

- 100% Polypropylene Construction

- Cartridges are Free of Surfactants, Binders and Adhesives

- Cartridges Materials are FDA Listed for Food and Beverage Contact

- Materials are NSF Certified

| 1_puris-fine_series,_mb,_filter_cartridge.pdf | |

| File Size: | 1315 kb |

| File Type: | |